The story:

Terry just had surgery and has difficulty moving around while he is recovering.

Needs of the robot:

-Follow a path (black line)

-Pick up and deliver a bottle or what ever Terry needs

-Reach Terry in a comfortable area while he is sitting (18" high)

-use only one Tetrix kid and one Mindstorms kit

Problems:

-DC motors are very strong and powerful but they have lots of friction. When you want to make a line follower you usually need slow moves, so that the common solution is to gear the wheels down.

But in my case I had a problem: the servos are very accurate but not very powerful, so if you want to lift a bottle in Terry's reach, you have to use 2 servos parallel or build a transmission. But in one kid are only 4 gears and only 2 servos (and one I need for the grapple mechanism) so I used the following configuration:

-2 wheels are coupled directly to the DC motors

-4 gears and one servo to build a strong lifter

-1 servo for the grapple mechanism

More problems:

The biggest issue was: how to reach the height with one servo?

The more you gear, the less effective angle you receive, in result you have to choose a longer lever which means bigger forces.

Which effective angle I mean? One servo can make 180 degrees, if you gear it 2:1 you receive an effective angle of 90 degrees, with a gear step 4:1 you receive an effective angle of 45 degrees.

After several tests and transmission configurations the lifter still has problems to lift a bottle (with the longest lever).

I wasn't satisfied at all and so I searched for other solutions.

2 possibilities to try:

-work with kinetic structures to increase the reach with a smaller lever

-increase the strength of the servos by changing the affect point of the forces

I went the way to help the servo to carry up the bottle with a counter weight (I took batteries and a lever). This solution was very effective.

The last problem was still existing: the friction of the motors.

While following the line, it could happen that the motors get a very low energy input (lower than the motors need to override the motor intern friction). In this case the only thing you can do is to kick the lazy robot's a... :)

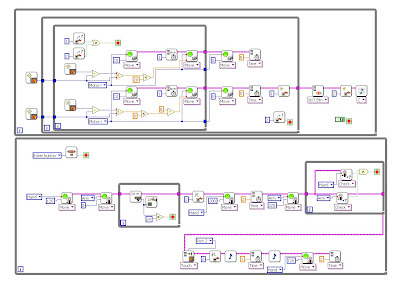

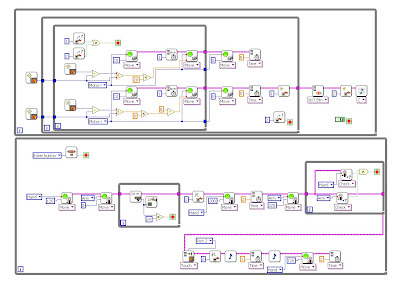

No not at all the solutions are very simple: before every new power order, you have to give the motors a quick power boost.

This is the final robot:

And of course the movie:

And of course the movie: